Think quick! Name an industry that’s saw its fleet shrink by 37 per cent in five years, yet its primary production increased?

Trucking? Faming? Beef? Potash? Uranium? Rail? Ocean-going shipping? Cucumbers?

Ding ding ding! Times up.

That industry is the oil and gas drilling industry. From October 2014 to mid-January 2020, the drilling rig fleet has declined from 811 to 515.

In the same time oil production has increased. Over the last five years, Canada’s oil production has grown from just under four million barrels per day to just under 4.5 million bpd.Ìý

I write a lot about drilling rigs, and the number of rigs working, because it is, by far, the leading indicator of the health of the industry. Yes, Canada produces most of its oil from the oilsands. But of that oilsands production, half comes from mining, and half comes from drilling, and that requires drilling rigs working.

I’ve spent time over the past few months thinking about this, absorbing it. The implications of this are tremendous. That’s why it was the focus of the February edition of Pipeline News, which you can find at Pipelinenews.ca.

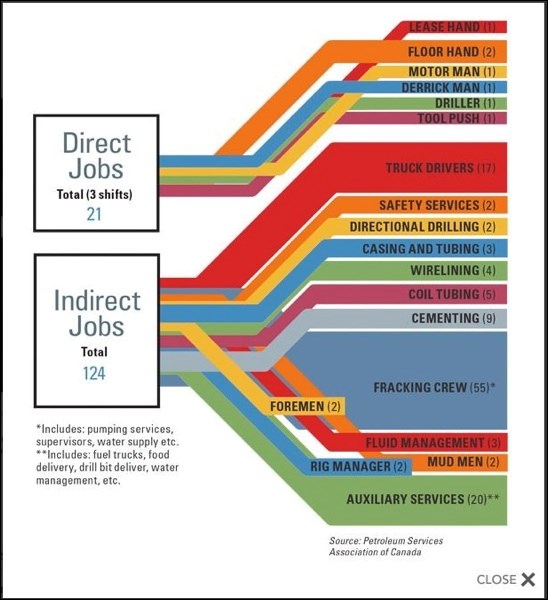

First and foremost are the number of jobs. The number I was given from the Petroleum Services Association of Canada and from the Canadian Association of Oilwell Drilling Contractors was 175 and 220. (One graphic showed 135 jobs).

I personally think those numbers are high, too high, inflated even. Some of the assumptions are that a frack crew of 55 work on each well, but not all wells are fracked. But even if you took half of that and said 100 jobs were directly and indirectly associated with each rig working, seeing the fleet shrink by 300 is mind blowing. That the CAODC thinks the fleet could contract another 100 is even more so. That’s half, folks. Half.

I don’t have a timeline on when that next 100 might disappear off the books, but within two or three years wouldn’t surprise me. And they might as well disappear off the books now, because they’re not working anyhow.

With the dramatically reduced drilling fleet comes a dramatically reduced number of active rigs, that is rigs that are actually working, with full crews, making hole. This is the busiest time of the year for drilling, and there are 268 rigs working. About eight years ago, the number was about double that. I recall seeing numbers of active rigs closer to 600 at times. Now, if every rig left was drilling, we couldn’t hit anything close to 600.

What has caused this? Obviously the oil downturn, with oil prices down significantly to the US$100 per barrel the industry had become accustomed to is the most important factor.

Some would say that maxed out export pipelines means that even if we wanted to produce a lot more oil, we couldn’t, because we don’t have the additional pipelines to ship it.

But the real, underlying reason has been the dramatic increase in rig efficiency. Much of the efficiency has been driven by the reality of trying to still make money off of oil that’s getting half, or less, per barrel compared to a few years ago.

The reality is our rigs are incredibly more efficient than they were 10 years ago, and generally speaking, with the same rigs. They might have bigger pumps now, and be running PDC bits, but they’re the same chassis.Ìý

I drive a 2011 Ford Expedition, around the same vintage as most of the newer rigs, since next to no new rigs have been built since 2014. Imagine if my Expedition now got 40 miles to the gallon, instead of its original 20. That is, quite literally, what has happened with the drilling industry.

I quizzed several people who had actual experience pulling the trigger on multi-million dollar decisions when building rigs.

The biggest impact has been the near universal implementation of the polycrystalline diamond cutter (PDC) bit. It was the eventual full appreciation of what that bit could do that drove up tremendous increases in horsepower in pumps, stronger pipe, mechanized pipe handling and vastly improved drilling muds and solids control.

I’ve stood on drilling floors where the roughnecks didn’t have enough time to grab a smoke between connections. (A connection is when they add the next 10- or 15-metre joint of pipe to the drill string.) As I once said to a drilling company owner, to go any faster, they’d have to take a laser off a star destroyer from Star Wars and put it on the bit.

This is to say nothing of the improvements in directional drilling.

The next big technological leap being implemented is walking rigs. That’s a rig that can move itself over a dozen metres or so and start drilling another hole, without being taken apart and reassembled. They are becoming more and more prevalent, to the point where in some regions they are becoming close to standard. Establishing a pad and drilling a pile of holes also means you have dramatically fewer leases, and correspondingly, less land disturbance. It also means less work for the lease and road builders.

We are seeing a step-change in the industry. Decades in the future, this period will be identified as being seminal in the oil industry. It’s going to affect everywhere from Gull Lake to Onion Lake, Kindersley to Carnduff.Ìý

We’re still figuring it out what it all means. But one thing is for sure:

It means less jobs.

Ìý

Brian Zinchuk is editor of Pipeline News. He can be reached at [email protected].

Ìý